Customization and Integration

Tailor NDI’s optical measurement and electromagnetic tracking solutions to your unique tracking application with diverse customization and integration options

OEM Product Requirements, Processes, and Timelines

The Polaris® optical measurement solution, and Aurora® and 3D Guidance® electromagnetic tracking solutions can be seamlessly integrated with OEM medical devices, bringing 3D tracking into their application workflows. Many aspects of NDI’s hardware components and tools are customizable, so that the final tracking application, as well as development and integration work, best meet the OEM’s product requirements, processes, and timelines. In addition, our software packages allow customers to easily configure and characterize both ready-to-use and developer kit tools.

NDI combines flexible customization options with a hands-on integration approach, working closely with your team to bring your tracking application to market.

Polaris Customization Options

The Polaris solution offers four different optical tracker models, each with distinct options and specifications relating to hardware size, measurement rate, measurement volume, latency, accuracy, data connectivity and mounting. Available options such as the Positioning Laser, Extended Pyramid Volume, and Radiation Hardening further expand system functionality.

Although the form factor of the optical tracker is fixed, the parameters of how it tracks, and the design of OEM rigid bodies and tools, are highly configurable. With so many options that enhance versatility and utility, no two Polaris solutions are exactly alike – each is unique to its specific medical device OEM customer.

- Four different models of optical trackers

- Four types of navigation markers

- Custom OEM Bezel (to match OEM branding)

- Myriad options for creating custom OEM tools

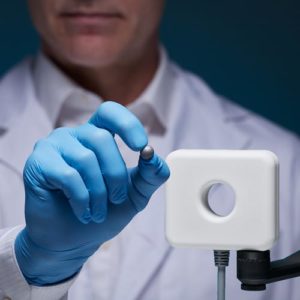

Aurora Customization Options

Almost every component and sensor of the Aurora solution can be customized to meet the most challenging tracking requirements for the most intricate OEM surgical applications. The medical device OEM decides the level of customization and extent to which they integrate Aurora components within their image-guided surgery or interventional systems.

With medical procedures becoming increasingly more complex, most medical device OEM customers choose to maximize the customization options provided by the Aurora. In such cases, the Aurora components seem to ‘disappear’ into the OEM medical system, its capabilities merging seamlessly with that of the OEM host application.

- Customized field generators are part of the system workflow.

- Customized electronic components allow for different system configurations.

- Customized sensors and tools for unique tracking requirements.

- Customized services including tool design, sub-tool assembly, and tool characterization.

Electronic components are available in both enclosed and PCB versions to facilitate standalone applications and easy integration into OEM carts, respectively.

3D Guidance Customization Options

The 3D Guidance solution is designed for immediate integration and use. Its electronics units and transmitters come ready to integrate, and its sensors are fully assembled. The driveBAY electronics unit fits seamlessly into the drive bay of a computer, OEM imaging cart, or training phantom. The trakSTAR electronics unit is a standalone unit that draws its own power.

Both the Mid-Range and Short-Range Transmitters can be mounted to—and even inside—the OEM interventional system or trainer. Although it may offer fewer customization options than the Aurora solution, the 3D Guidance solution still provides numerous ways in which it can be tailored to the medical device customer’s system form factor and tracking requirements.

Book a Free Consultation

Let’s discuss your unique application and customizations.

Technology Comparison

Compare our Optical Measurement and Electromagnetic Tracking solutions.