3D Guidance® Transmitters

Two transmitter sizes are available for a range of OEM tracking applications, from ultrasound probe tracking to guided needle biopsies.

Flexible Integration into OEM Imaging Systems, Trainers, and Carts

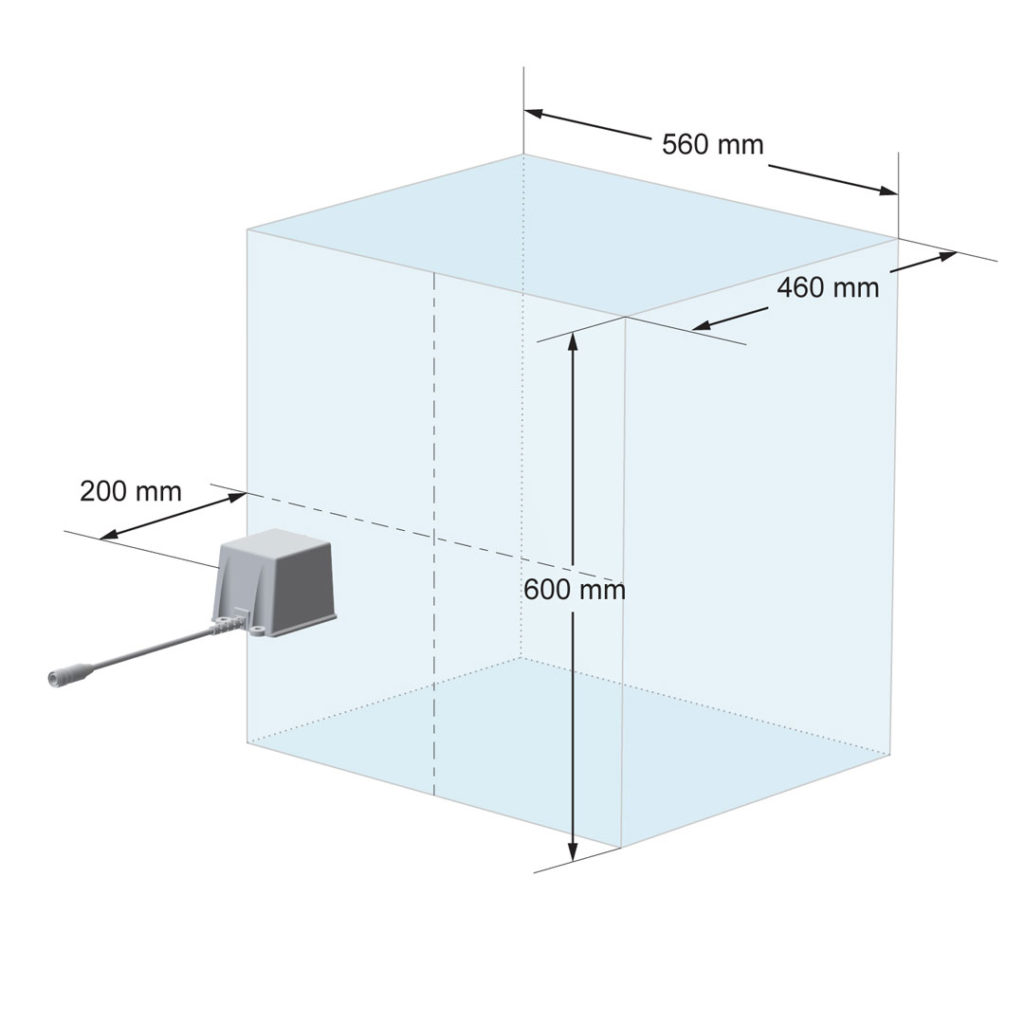

3D Guidance® Mid-Range Transmitter

The Mid-Range Transmitter (MRT) offers a flexible setup that can be integrated into OEM applications where the tracking volume needs to cover a larger region. The MRT is a general-purpose transmitter (field generator) and is used in a wide range of OEM system navigation applications in interventional imaging, such as ultrasound probe tracking, ultrasound-guided needle biopsy, and robotic surgery.

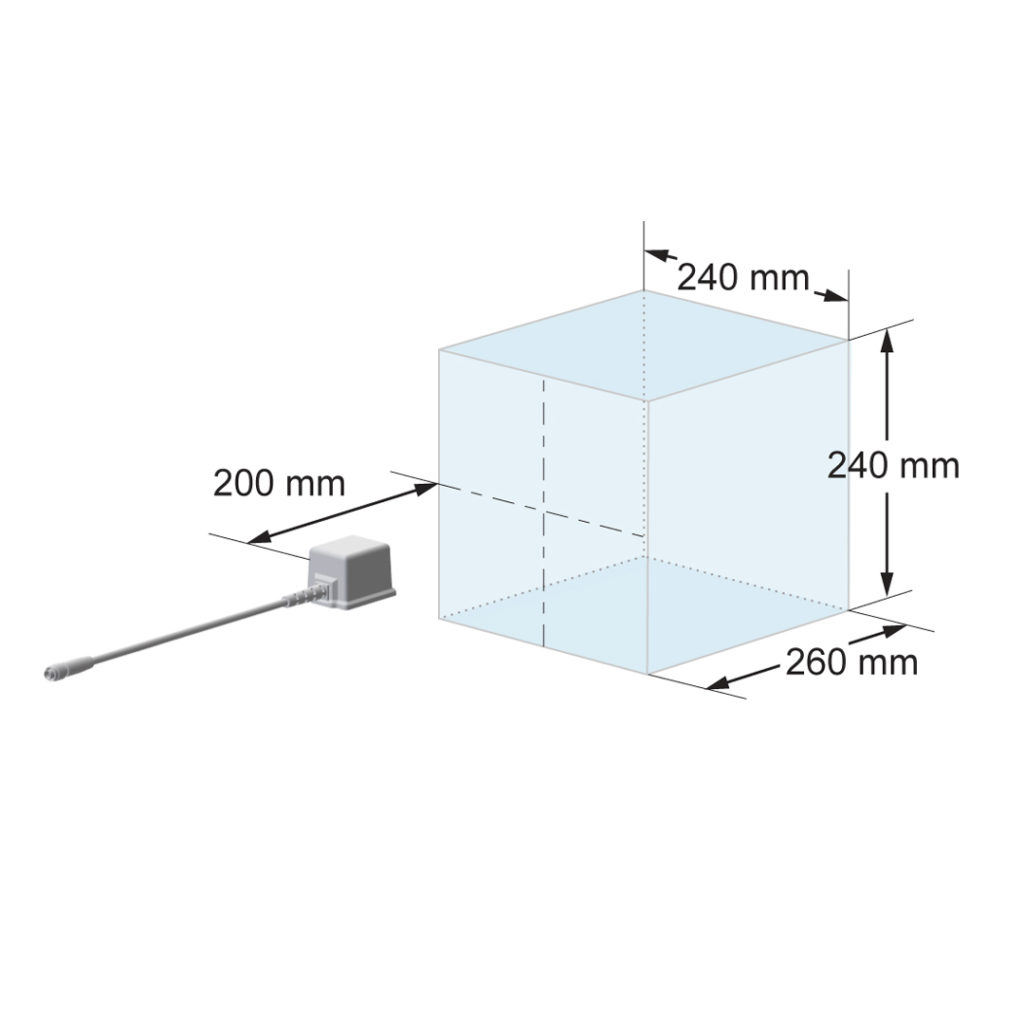

The size of the measurement volume is specific to each 3D Guidance sensor, which is determined by the tracking distance achieved on the transmitter’s X, Y, and Z-axes. Larger sensors have a longer tracking distance on each axis, resulting in a larger overall measurement volume.

| RMS | |

|---|---|

| Accuracy – 6DOF Sensor | |

| Position | 1.40 mm |

| Orientation | 0.50° |

| Specification | Value |

|---|---|

| Translation Range | ± 76 cm in any direction |

| Angular Range | All attitude: ±180 deg azimuth and roll, ±90 deg elevation |

| Update Rate | Up to 765 updates/second |

| Measurement Rate | 80 Hz default; configurable from 20–255 Hz |

3D Guidance® Short-Range Transmitter

The Short-Range Transmitter (SRT) provides a smaller measurement volume for localized tracking in confined, difficult-to-access regions. Its small, lightweight design allows the SRT to be mounted directly on third-party mobile imaging equipment, or inside OEM system surgical simulation phantoms.

| RMS | |

|---|---|

| Accuracy – 6DOF Sensor | |

| Position | 1.40 mm |

| Orientation | 0.50° |

| Specification | Value |

|---|---|

| Translation Range | ± 45 cm in any direction |

| Angular Range | All attitude: ±180 deg azimuth and roll, ±90 deg elevation |

| Update Rate | Up to 600 updates/second |

| Measurement Rate | 80 Hz default; configurable from 20-255 Hz |

Learn how Electromagnetic Tracking works.

Download our 12-page Education Guide to learn how you can integrate Electromagnetic Tracking Technology into your OEM medical devices to:

- Navigate instruments safely and reliably through complex anatomy.

- Target small treatment areas with

sub-millimeter accuracy and precision. - Visualize real-time position as well as orientation of an instrument.

- Track instruments even when they

are out of sight. - Embed micro sensors into flexible and

rigid instruments.

Legal Disclaimer

NDI tracking and measurement products are general metrology components that can be integrated into customer products, research experiments, and/or as components of medical devices that require precision measurement and tracking. While NDI components and technology can be integrated into original equipment manufacturer (OEM) medical devices, they are not specifically intended for a given application and, as such, have not been developed or manufactured in accordance with medical device standards. It remains the responsibility of the OEM customer or end-user to determine and test the suitability of NDI components and technology for their intended use, including performing any required ethics approval, verification, and validation required to demonstrate suitability and compliance. System-level testing, certification, and validation are the responsibility of the original equipment manufacturer or the applicable end-user and should be completed prior to the use of NDI products or technologies in any application.

*reduced specifications with optimized system settings