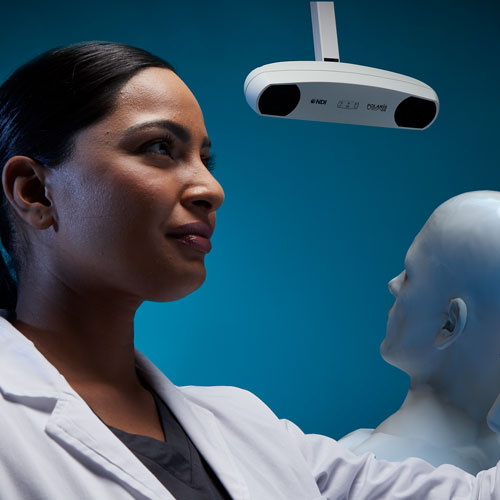

Compact Optical Tracker for Small OEM Instruments

The Polaris Vicra® shares the same trusted measurement performance as all Polaris optical trackers, but in a smaller form factor. Its compact size can allow medical device OEMs to integrate the Polaris Vicra into surgical workflows that require smaller instruments and where equipment or operative space is limited.

Exceptional Measurement Accuracy

The Polaris Vicra tracks 3D tool positions with sub-millimetre measurement accuracy and repeatability. The most subtle OEM surgical tool movements are precisely tracked and localized in real-time, with volumetric accuracy to 0.25 mm and 95% confidence interval of 0.5 mm.

Compact Hardware Design

The Polaris Vicra features a compact form factor and weighs just 0.8 kg. It can be mounted or transported almost anywhere – even in areas where equipment or operative space is tight. Its portable design is enhanced with a pre-calibrated measurement volume and quick system start-up.

Optimized Measurement Volume

The Polaris Vicra has a smaller measurement volume that is optimized for targeted tool tracking within localized areas. Polaris Vicra tool geometries are correspondingly reduced, which allows for lighter and more ergonomic OEM instruments that allow very precise movements.

Customizable System Implementation

The Polaris Vicra comes with different software utilities to customize how the optical tracker and tools interface with the OEM host application. Tool geometries and other tracking parameters are set by a tool definition file, while a built-in API speeds application development and integration.

Contact our team to learn more about NDI’s Polaris Lyra.

Download Our 13-Page Guide To Learn How Optical Tracking:

- Helps to visualize and accurately track instruments within a large volume.

- Enables OEM solution providers to integrate tracking into their workflows to improve patient outcomes.

- Supports integration with robotic-assisted systems and augmented reality applications.

Legal Disclaimer

NDI tracking and measurement products are general metrology components that can be integrated into customer products, research experiments, and/or as components of medical devices that require precision measurement and tracking. While NDI components and technology can be integrated into original equipment manufacturer (OEM) medical devices, they are not specifically intended for a given application and, as such, have not been developed or manufactured in accordance with medical device standards. It remains the responsibility of the OEM customer or end-user to determine and test the suitability of NDI components and technology for their intended use, including performing any required ethics approval, verification, and validation required to demonstrate suitability and compliance. System-level testing, certification, and validation are the responsibility of the original equipment manufacturer or the applicable end-user and should be completed prior to the use of NDI products or technologies in any application.